Blog

MISys Manufacturing – Calibrated Measurement and Inspection Tooling Records

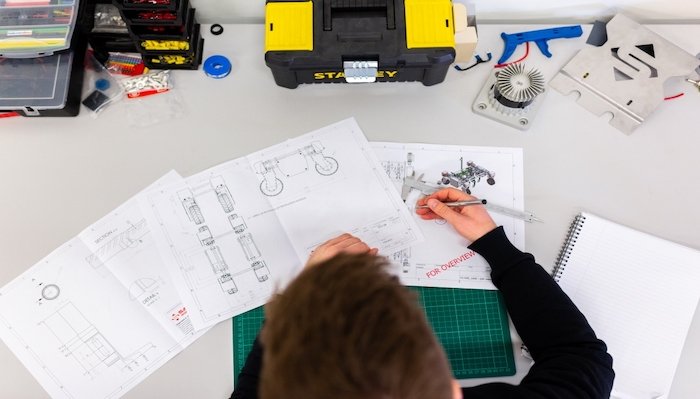

Manufacturers rely on measurement devices for production and inspection. Some of those devices may be calibrated within a Quality Management System (QMS) and therefore need to be logged to maintain tooling records. MISys has a Tooling register that works well to maintain the Calibration requirements and includes reports that notify of upcoming maintenance due dates for calibration.

MISys Manufacturing – Database Confusion

When there is more than one database available in the system (e.g., Live/Production & MITESTCO/Test database), there is a risk of logging into to the wrong database and transacting there.

MISys Manufacturing – Determine Inactive Items using a Master Production Schedule.

Knowing which items are required for future production is the foundation of good materials management. Similarly, knowing which items are not required allows for setting those items as inactive and potentially purging them. Doing so provides value because it directs organizational efforts on the needed items and away from what is not needed. A couple related examples are that of stockroom space can potentially be freed up and balance sheets will become more accurate.

MISys Manufacturing – Lead time Confusion

Why are there multiple fields in MISys to enter Order Lead and what does ‘Order Lead’ refer to?

Let’s start with the basics; ‘Order Lead’ in MISys is refers to the time that is needed for purchased items to arrive to the shipping location after placing the Purchase Order (PO) with the supplier. These are calendar days (7 days/week).

MISys Manufacturing – Checking for Recursive BOMs

As per MISys, “a Recursive BOM is a bill of material that includes itself as a component”.

MISys Manufacturing – Deleting Obsolete Items

Over time, the master files in MISys increase in size and can slow down the system. It’s surprising to find out that many times, master files that were created for a purpose were never used. This creates unnecessary data pollution and can easily be rectified.

MISys Manufacturing – Changing Item No. – Part 2 - Range of Items

Following from Part 1 of ‘Changing Item No.’ blog, let’s see how to make changes to a range of items’ Item No., instead of a single item.

MISys Manufacturing – Stock Unit vs. Purchase Unit

MISys allows users to set a specific unit of measure for each supplier of an item that might be different than the Stock Unit of Measure (UoM) of that item. This is referred to as the Purchase Unit of Measure (PUoM).

MISys Manufacturing – Modify Custom Labels using MISys EXT

MISys EXT is a great interface for printing labels for MISys transactions. In this example a custom label has been created called ‘Receiving’ and set as the default when items are received against a Purchase Order.

MISys Manufacturing – Alternate to Changing Item Type

Sometimes it may be necessary to change the ‘Item Type’ of an item after a while. However, if certain conditions are not met, this will not be possible to do.

MISys Manufacturing – Changing Item Type

MISys requires an ‘Item Type’ to be assigned to each item as Raw Material, Resource, Assembled, Bulk Issue or Outside Processing. However, sometimes it may be necessary to change the ‘Item Type’ of an item after a while.

MISys Manufacturing – Transferring Items to Sales

For companies that maintain sales inventory for a customer facing retail or distribution presence, MISys can maintain Sales Stock to pre-defined levels. In turn that sales stock qty provides the sales team with visibility of on hand inventory that can be shipped directly from the warehouse when customers are placing orders.