MISys Manufacturing – Lead time Confusion

Why are there multiple fields in MISys to enter Order Lead and what does ‘Order Lead’ refer to?

Let’s start with the basics; ‘Order Lead’ in MISys is refers to the time that is needed for purchased items to arrive to the shipping location after placing the Purchase Order (PO) with the supplier. These are calendar days (7 days/week).

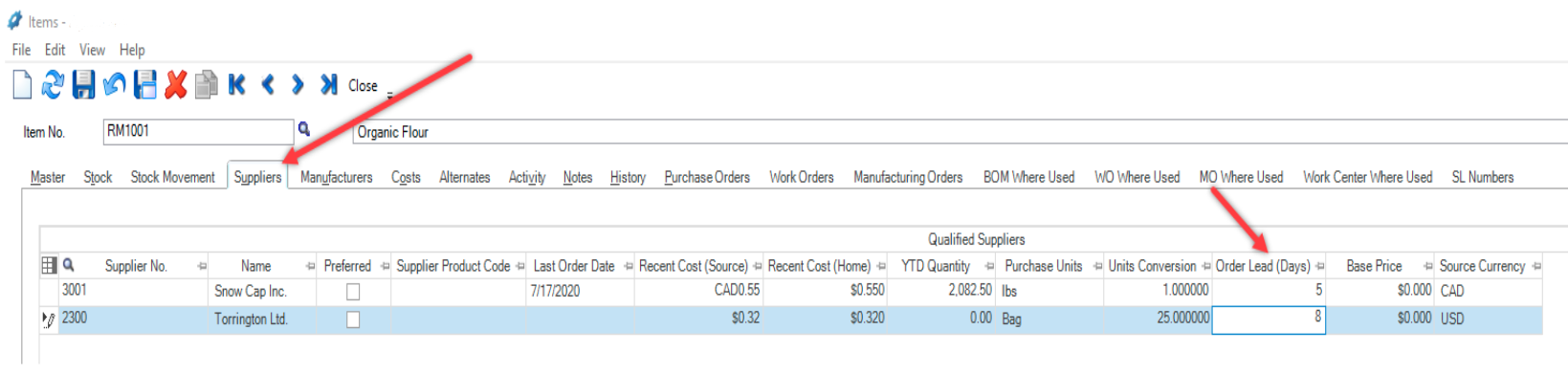

Where to enter ‘Order Lead’ and why in multiple places? ‘Order Lead’ must be entered either in Master Files | Items ‘Suppliers’ tab or Master Files | Suppliers ‘Items’ tab. The ‘Order Lead’ entered in these fields is supplier and item specific and will be used by MISys when creating POs specific to the corresponding item and supplier. MISys will use the ‘Order Lead’ days to calculate the ‘Initial Due’ date of a PO by adding the ‘Order Lead’ to the ‘Order Date’ of the PO.

Second place where MISys asks the user to enter ‘Order Lead’ is in Master Files | Items, ‘Stock’ tab. The ‘Order Lead’ in this field is item specific, but not supplier specific. MISys uses this field when using MRP to calculate Scheduling dates for POs. Common practice is to enter the longest lead time of all your suppliers as the ‘Order Lead’ in this field to ensure safe scheduling calculations by the MRP module. In the provided screen shots, one supplier has an Order Lead of 5 days, and another supplier has 8 days for item RM1001. The ‘Order Lead’ on the Item Master ‘Stock’ tab is entered as the greatest of these two values (i.e., 8).

If you have any questions about entering lead times in your MISys system, please feel free to contact us here at Central Nervous Systems.