Manufacturing Improvement – Routing Operations

The term Bill of Material (BOM) can be misleading because in many manufacturing systems, the BOM can contain not only Materials, but also Routing Operations like a recipe. When Material is combined with Operations, the Bill of Material is often referred to as a Bill of Manufacturing. The Bill of Manufacturing, when converted to a Production Order, enables Work Center scheduling and the capability to budget the costs of production and subsequently track though-put speeds along with Work Center labor and overhead costs. The addition of Operations, therefore, can provide a much deeper level of intelligence into manufacturing performance which, in turn, helps to identify the prime targets for manufacturing improvement.

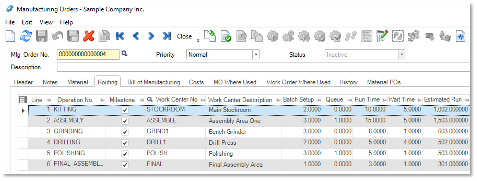

The following view of Routing Operations comes from a Lighting sub-assembly Manufacturing order in the MISys Manufacturing Sample company. Each operation in this build is associated to a Work Center and has four timing elements that are either duration based, or effort based and populated with time as applicable.

The addition of Operations to the Bill of Material provides the capability to budget and track actual speeds and costs for production. Since speed and cost are typically the top areas for manufacturing improvement, the addition of Operations is often an important step in establishing a functional continuous improvement environment.

Matt.